Apogee

Prepress workflow & automation software

Any organization can benefit from the Apogee suite of workflow management products. With Apogee, ECO3 offers you a comprehensive and integrated workflow solution. It is designed by professionals for professionals and committed to offering the highest degree of reliability.

Keeping an overview of your PDF files with Apogee Preflight? Calculating the ideal imposition with Apogee Impose? Or saving on ink costs and expensive press time with InkTune? Choose without losing thanks to Apogee. It perfectly aligns and fuses different software modules into one streamlined whole.

With Apogee, you control every phase of the production process from a single user interface. Even jobs that consist of multiple parts are simply processed in one flow. The latest version brings new tools, improved performance, and a unique cloud-based solution.

“We installed Apogee 20 years ago, and it is working great for us. The use of built-in automation and integrated trapping has made a big difference in our overall productivity. The automation has only gotten better. What we do now takes half the amount of people which makes my job easier. Apogee is reliable, intuitive, faster, and easy to use, and it has only improved. ”

——Beth Brandewie, Prepress Manager - Globus Printing & Packaging

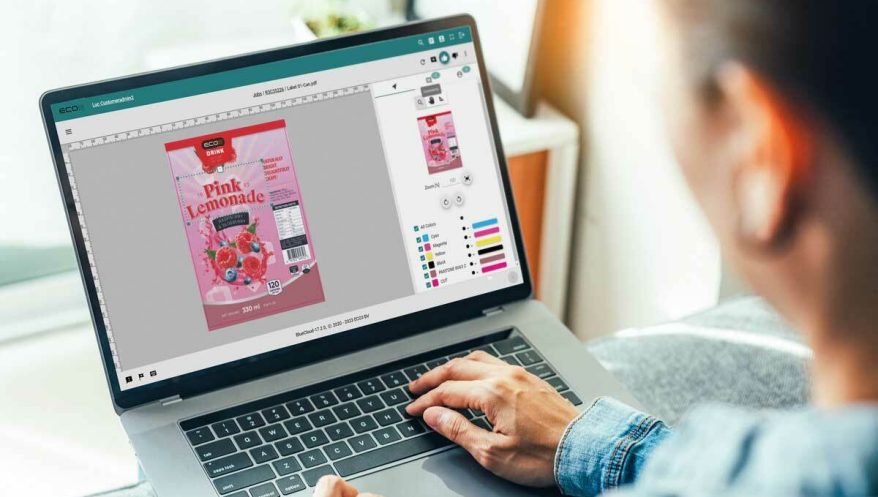

New in v13: extended packaging support

Apogee v13 offers operators a dedicated toolbox to review packaging designs, nest them to optimize media usage and generate die cuts. Using a single workflow for both commercial printing and packaging jobs limits training costs, minimizes licensing and hardware investments and increases flexibility.

New in v13: connecting quality

ECO3’s PressTune manages print quality using spectral data, while also taking TVI into consideration. Calibration curves are automatically sent to Apogee v13 and those data can immediately be used to output new plates that deliver print quality according to the agreed quality standard.

New in v13: APPE 6

Including version 6 of the Adobe PDF Print Engine ensures Apogee is fully compatible with the new PDF 2.0 standard.

New in v13: automating versioning

Job setup can be automated using data provided in a Microsoft® Excel spreadsheet. This saves operator time and avoids costly errors.

Performance and reliability due to Digital Quick Strip

Thanks to its unique Digital Quick Strip (DQS) mechanism, Apogee provides you with unprecedented efficiency and user-friendliness. It lets you process each page separately before integrating it into a place holder, which turns page revision into a swift and simple task. As your layout is also rendered as a separate file, updating it only takes a few minutes. By relying on DQS, you increase throughput and optimize the usage of all available output resources.

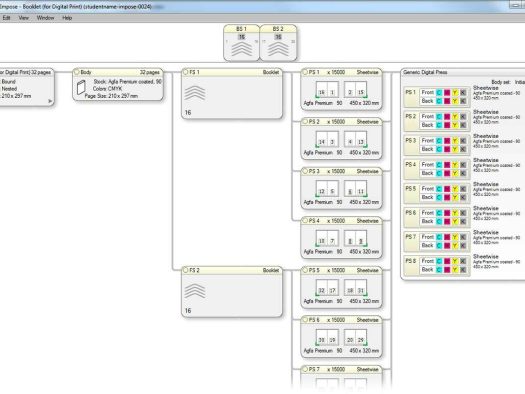

Press efficiency and order combination

Apogee can combine print jobs intelligently to optimize press time while keeping track of the actual order. It caters to the needs of printers faced with shortening run lengths and looking for ways to keep their presses running as efficiently as possible to maintain sustainable margins. The automation goes beyond combining orders (or parts of orders) on a single press sheet. Apogee makes it easy to still keep track of the separate orders and allows for proper finishing. Collation marks, signature barcodes and all other marks remain in place and refer to the original order.

Maximum ease of use

Apogee enables you to keep track of all required steps in the prepress process working from one place. Extended JDF and JMF support also improves the connection between software and devices, and thus the communication with the user. Moreover, Apogee users can now split JDF files, making your production process easier than ever.

ATP or Automate Task Processor

Accessible automation is part of the Apogee DNA: The user interface offers multiple ways to automate standard and repetitive tasks such as job archival and deletion. You can also effortlessly set up page placement rules according to naming conventions. Automation is now lifted to the next level with ATP or Automate Task Processor. Using an interface, rules are defined to take action depending on a page’s content or meta data. This means that pages and orders can be routed to specific production plans. In case of a high copy count, an order is sent to your offset press. A digital job may be split between your B&W and color digital presses to guarantee the lowest possible production cost. ATP is not limited to the rules set in the interface. If dedicated actions need to be taken, specific scripts can be written and added. This leads to the highest possible degree of automation of your prepress production.

Apogee 服务器

系统要求 | Windows 10、Windows 2016(标准版)或Windows 2019(标准版),具体取决于生产量和可靠性要求 |

|---|---|

硬件要求 | 双CPU,最小16GB运行内存和250GB硬盘内存。 |

Apogee 客户端

系统要求 | Windows 8, Windows 10, Windows 2012, Windows 2016 and Windows 2019 |

|---|---|

语言 | 中文(简体和繁体)、捷克语、荷兰语、英语、芬兰语、法语、德语、希腊语、意大利语、日语、韩语、挪威语、葡萄牙语、波兰语、俄语、西班牙语、瑞典语 |

Apogee 产品资料